Homepage

About our firm

Products

Contact us

Signaling, dozing and control system

Signaling limits of weighting mass.

Each scale of MENSOR company is equipped with the indication of signaling limits of weighing mass system illustrated on the display of the scale.

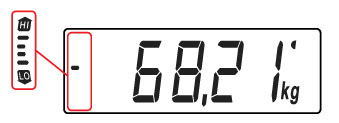

On the left side of the display scale is vertical line placed at the bottom completed with "LO", from the top with "HI". After start function of signal levels and programming, both of values: the mark “LO” is indicated for the load value smaller threshold – the mark “HI” for the value bigger from the top threshold (left semi-circle in the upper right corner of the display). For the load between “LO” and “HI” is indicated of horizontal line. Its position is proportional to the load. This function works fine in normal weight. The values of "LO" and "HI" are always positive.

Fig. 1 Display with the mark: “LO” and “HI”

Optionally, the scale can be equipped with light-emitting diodes in the front panel acting (like) as characters, "" LO "and" HI ".

The scale can be optionally equipped with a horn, signaling indications from the interval <"LO", "HI">. Also, the scale can be optionally equipped with two independent relays shorted or open properly when crossing levels "LO" and "HI". Sounder and relay outputs can operate only when the scale has power supply. In case battery supply, only indications on the display are possible.

Threshold values can be put into the scale from the computer, or by placing appropriate mass on the pan. Optionally, you can also enter values from the keyboard scale.

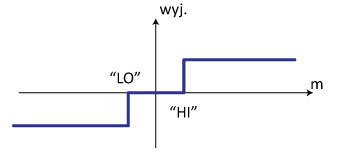

The use of signaling system limits of mass described above can be varied. For example, this system performs the functions of the measured three-position controller where the interval between "LO" and "Hi" is a dead zone and the level of control, is the set point by “LO” and “HI”, Figure 2

Fig 2 Diagram of the three-position controller

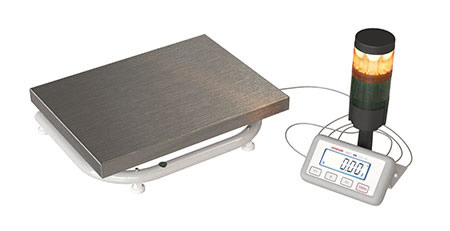

A simple application of signaling limits of weighting mass system is connected to the scale by a conspicuous light lamp indicating one limit value fig. 3, or two values: "LO" and "Hi" fig. 4

Fig. 3 The scale type WM3P3 30x40 with one lamp indicating a limit threshold value

Fig. 4 The scale type WM3P3 30x40 with two lamps indicating a limit threshold value

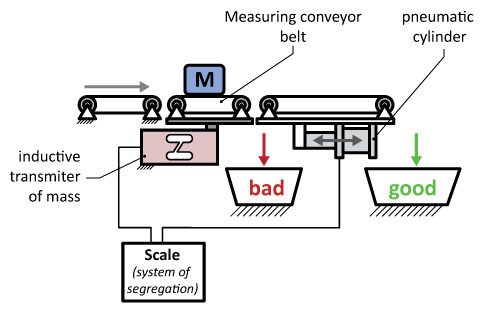

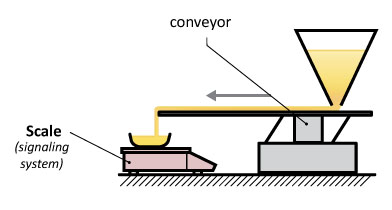

Electronic scale of MENSOR company equipped with an signaling limits of weighting system can also work as a controller segregated for good elements with correct weight and the wrong, which does not meet the criteria established mass fig. 5. Elements weighing on the first feeder having incorrect mass, below “LO” , fall into the first container as wrong, but those elements which weighing more than "HI" fall into the container as "good".

In the case of normal mass-weighted elements on the first feeder the scale is controlled by relays actuator such as a pneumatic cylinder, which moves the second feeder to the first one to get weighed elements and send them to a container of "good" elements.

Fig. 5 Diagram of elements selection according to criterion based on the measurement of mass

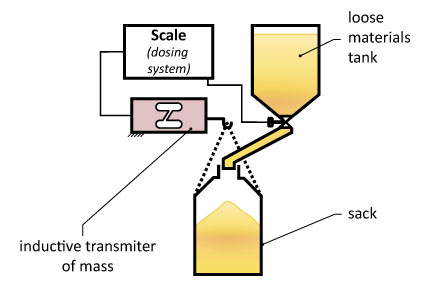

A typical application of scale equipped with the limits signaling system of mass is portioning of loose materials fig. 6. Mass of the bag, which is filled with loose material is weighted by the inductive transmitter of mass . At a given value of "HI" with the relay and actuator the scale shuts of material from the tank into the bag. In this case, the dosing process, restart manually after removing the filled bag and replace it with an empty bag.

Fig. 6 Dosing system for loose materials

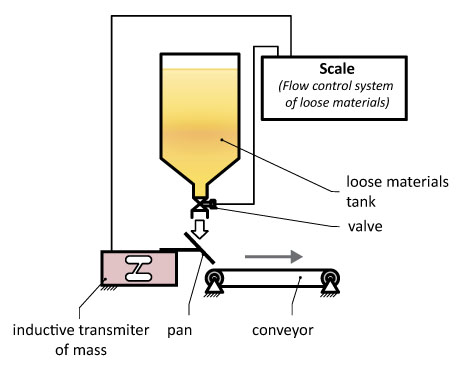

Example control flow of loose material shows on Figure 7. Loose material falls on the inclined plate connected with inductive measuring transmitter. The force component acting on the plate is the input of the scale and it value depends on the flow of material falling on the plate. Too high flow causes the signal "HI" and scale through the relay closes the valve located at the outlet of the tank. In the case of small flow metering valve is little open.

Fig. 7 Diagram of the flow control of loose materials

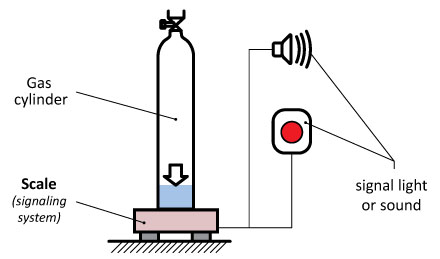

A common use of signaling limits of weighing mass system is control the content of gas in the cylinder. In the case of gas supply devices requiring continuous operation is required signaling of minimum gas in the cylinder, to replace it.

Putting on the scale cylinder equipped with a signaling system we solves this problem Figure 8 In general, is required special design for mounting high cylinder on the platform of scale - MENSOR company can solve such kind of problem.

Fig. 8 Signaling the minimum content of the gas in the cylinder

A similar example of a weighting to dispense bulk material as shown in Figure 5 is the smallest mass dispensing with vibratory feeder Fig. 9. This feeder is poured loose mass on the pan until it reaches before programming the value "HI". At this point, vibrating feeder is turned off and take a weighed mass from the pan - it can be a container, replaced by a blank. When you turn on the vibrating feeder repeating the dispensing cycle. In contrast to the example of Figure 5, we have here a much slower due to the filling of the container that is result of principle a vibrating feeder.

Fig. 9 Dosing system for loose materials with vibrating feeder

MENSOR give two year's warranty for Signaling, dozing and control system.

Signaling, dozing and control system

Additional options:

- lion battery (up to 50 hours continuous work): 15€

- output RS232: 8€

- output RS485: 20€

- program Genie is for design measurement and control systems - description of the program

- 2m cable connecting computer with the scale: 4€

- it is possible made special pan

MENSOR Poland, 04-689 Warsaw, Węglarska 50, tel/fax +48 22 613-08-74, tel.+48 22 424-33-23 www.mensor.pl ; mensor@mensor.pl